At Alpha Packaging, we specialize in packaging options that protect your products and make them look great throughout shipping, delivery, and unboxing. Foam inserts for boxes can fill up empty space in boxes without weighing them down or interfering with the product experience. We offer a variety of options to protect products of all shapes and sizes and we can create custom inserts for uniquely shaped items.

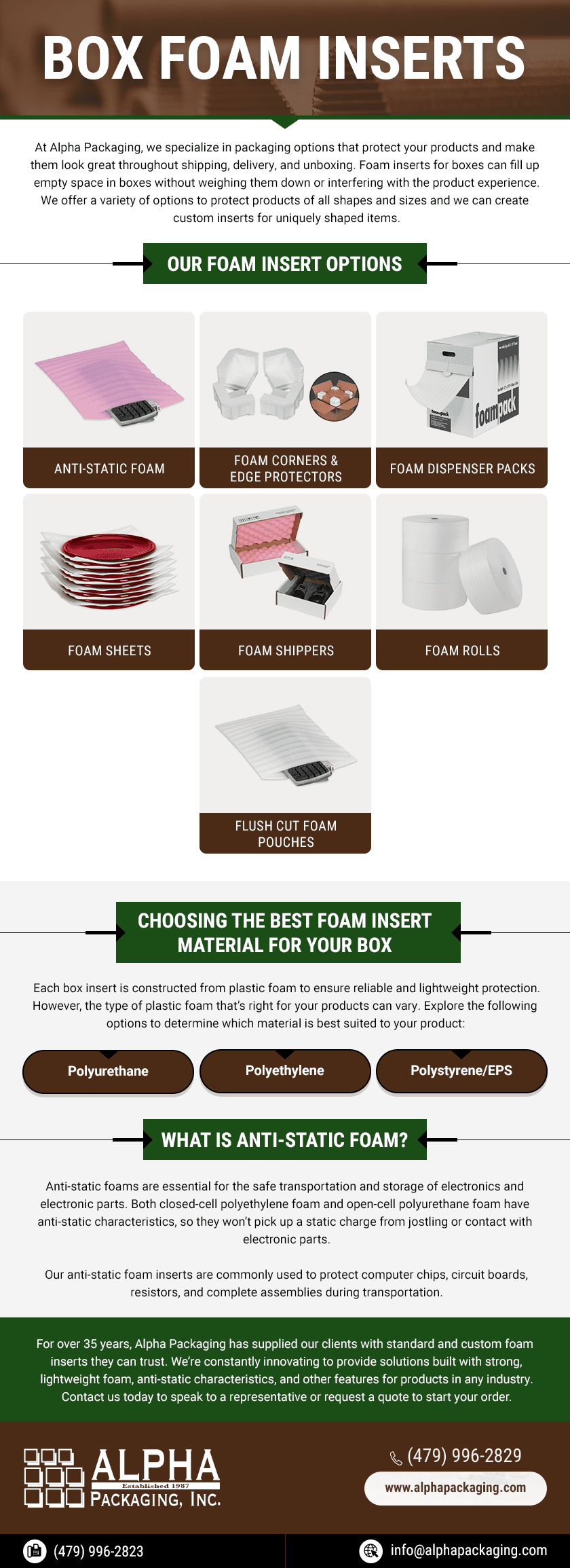

Explore Our Foam Insert Options

We manufacture a wide range of standard and anti-static foam inserts in multiple different shapes and sizes that shield products from jostling, scuffs, and breakage. Each shape is designed to provide optimal protection and cushioning based on the shape or needs of your product, such as its edges, surfaces, negative space, and more. Our product options include:

Choosing the Best Foam insert Material for Your Box

Each box insert is constructed from plastic foam to ensure reliable and lightweight protection. However, the type of plastic foam that’s right for your products can vary. Explore the following options to determine which material is best suited to your product:

Polyurethane

Polyurethane is a soft, flexible material that many businesses prefer for their standard foam inserts. It provides excellent thermal insulation across long supply chain journeys. At a density of only 1.6 lb per cubic foot, it’s lightweight enough to reduce excess shipping costs while still providing a flexible shield. This material can also dampen vibration and shock as part of its cushioning function.

Polyethylene

Polyethylene is harder and less flexible than polyurethane, making it the ideal choice for products with sharp edges or higher weights. Because it has a closed-cell structure, it can resist water absorption, reducing the risk of water damage or the growth of mold and mildew throughout storage. It is also more resistant to chemicals than other options. Because of its higher density (at 2.2 lbs per cubic foot), it performs better in terms of vibration and shock protection.

Polystyrene/EPS

Polystyrene foams are stiff, dimensionally stable, and low-weight. This makes them an excellent choice for filling gaps and negative space in potentially breakable products. Expanded polystyrene foam (EPS) is lightweight, with good moisture resistance and durability. It is often used in food packaging and insulation.

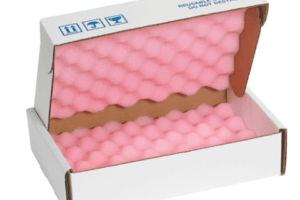

What Is Anti-Static Foam?

Anti-static foams are essential for the safe transportation and storage of electronics and electronic parts. Both closed-cell polyethylene foam and open-cell polyurethane foam have anti-static characteristics, so they won’t pick up a static charge from jostling or contact with electronic parts. Our anti-static foam inserts are commonly used to protect computer chips, circuit boards, resistors, and complete assemblies during transportation.

Custom Foam Packaging Solutions at Alpha Packaging

When your products need foam inserts with specific characteristics and dimensions, we’re here to help. Our team offers custom foam packaging design and manufacturing so you have the right packaging solution for unique products. We have decades of experience creating foam inserts with two-dimensional profiles or layers of foam or bubble sheeting with firm backing. Get precise custom solutions with our process backed by ArtiosCAD, automated cutting tools, and a dedicated designer. Each custom foam packaging solution is designed to provide optimal product protection, no matter the shape of the product, the complexity of its parts, or the length of its transportation and storage journey.

Contact Our Experts for Your Custom Foam Box Inserts Needs

For over 35 years, Alpha Packaging has supplied our clients with standard and custom foam inserts they can trust. We’re constantly innovating to provide solutions built with strong, lightweight foam, anti-static characteristics, and other features for products in any industry. Contact us today to speak to a representative or request a quote to start your order.