Due to the wide variety of automotive components on the market today, auto parts manufacturers also have particularly unique packaging requirements. Custom packaging design is often the only way to create automotive packaging built to withstand the rigors of long-distance shipping and frequent handling. Uneven weights, corrosive fluids, and complex multi-part assemblies further increase the need for safe, innovative automotive packaging designs.

Alpha Packaging leverages extensive industry experience and sophisticated packaging technology to provide industry-leading automotive packaging solutions. Our advanced design software and manufacturing equipment allow us to produce unique packaging products that provide optimal protection and cost savings.

Learn more about the benefits of custom automotive packaging solutions, the types of components that require specialized packaging, and Alpha Packaging’s capabilities.

Custom Packaging Services for the Automotive Industry

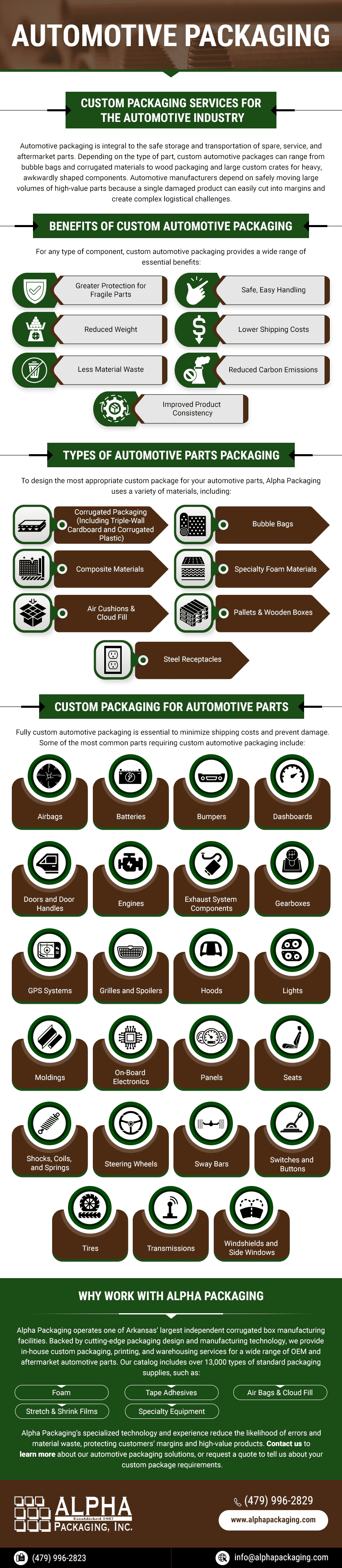

Automotive packaging is integral to the safe storage and transportation of spare, service, and aftermarket parts. Depending on the type of part, custom automotive packages can range from bubble bags and corrugated materials to wood packaging and large custom crates for heavy, awkwardly shaped components. Automotive manufacturers depend on safely moving large volumes of high-value parts because a single damaged product can easily cut into margins and create complex logistical challenges.

Benefits of Custom Automotive Packaging

It’s important to use custom automotive packaging with carefully matched dimensions, load capacities, and material properties. Auto parts come in a wide variety of shapes, sizes, and weights, including intricate assemblies that standard packaging leaves vulnerable to damage.

Engine and drivetrain crating, for example, must keep components secure while maximizing exterior storage space. Axle and transmission packaging requirements can be highly variable, requiring even more unique package designs. Even small, lightweight auto parts depend on durable custom packaging to protect sensitive precision-engineered components.

Custom package design is also the only effective way to protect custom assemblies or works in progress, which must remain secure and intact during transportation. For any type of component, custom automotive packaging provides a wide range of essential benefits:

- Greater protection for fragile parts

- Safe, easy handling

- Reduced weight

- Lower shipping costs

- Less material waste

- Reduced carbon emissions

- Improved product consistency

Types of Automotive Parts Packaging

Choosing the right type of automotive packaging depends on many factors. Oblong shapes, unevenly distributed weight, and the presence of corrosive fluids are just some of the unique factors custom package designers must take into account. It’s also common to use multiple types of packaging materials to achieve packaging design goals.

To design the most appropriate custom package for your automotive parts, Alpha Packaging uses a variety of materials, including:

- Corrugated packaging (including triple-wall cardboard and corrugated plastic)

- Bubble bags

- Composite materials

- Specialty foam materials

- Air cushions & cloud fill

- Pallets & wooden boxes

- Steel receptacles

Custom Packaging for Automotive Parts

Fully custom automotive packaging is essential to minimize shipping costs and prevent damage. Some of the most common parts requiring custom automotive packaging include:

- Airbags

- Batteries

- Bumpers

- Dashboards

- Doors and door handles

- Engines

- Exhaust system components

- Gearboxes

- GPS systems

- Grilles and spoilers

- Hoods

- Lights

- Moldings

- On-board electronics

- Panels

- Seats

- Shocks, coils, and springs

- Steering wheels

- Sway bars

- Switches and buttons

- Tires

- Transmissions

- Windshields and side windows

Why Work With Alpha Packaging

Alpha Packaging operates one of Arkansas’ largest independent corrugated box manufacturing facilities. Backed by cutting-edge packaging design and manufacturing technology, we provide in-house custom packaging, printing, and warehousing services for a wide range of OEM and aftermarket automotive parts. Our catalog includes over 13,000 types of standard packaging supplies, such as:

- Foam

- Tape adhesives

- Air bags & cloud fill

- Stretch & shrink films

- Specialty equipment

Our packaging capabilities meet complete knock down (CKD), medium knock down (MKD), and semi knock down (SKD) needs. Our design technicians are adept with ArtiosCAD, allowing us to quickly and accurately determine the exact structural properties required for any given automotive packaging challenge. This, along with our computerized sample cutting table, enables us to quickly create accurate prototypes and fine-tune the results before scaling up production.

Alpha Packaging’s specialized technology and experience reduce the likelihood of errors and material waste, protecting customers’ margins and high-value products. Contact us to learn more about our automotive packaging solutions, or request a quote to tell us about your custom package requirements.