Selecting the Right Corrugated Box

Although corrugated and cardboard boxes are often considered to be the same thing, they actually vary quite a bit in their structural composition. Cardboard consists of a single layer of either extremely thick paper or a heavy paper pulp, while corrugated boxes are layered to provide a lightweight yet durable, and therefore highly versatile, material construction. Corrugated boxes are perfect for custom or bulk shipping and reliable cross-country or worldwide goods transportation. Besides shipping solutions, other applications like retail displays and packaging utilize corrugated fiberboard.

This guide will help you understand the various corrugated box types we offer at Alpha Packaging, Inc., their construction, and how to choose among them.

Parts of Corrugated Fiberboard

Corrugated fiberboard consists of fluted paper, which is a heavy, wavy paper medium, adhered to a flat layer of linerboard. Both of these parts are made from containerboard, and the number of linerboard and fluted layers determines the strength of the corrugated fiberboard.

Board Types

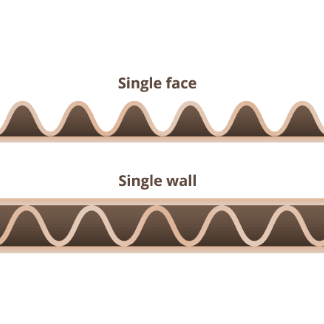

1. Single face

Single face. An optimal choice for interior packaging as it lacks the higher strength of other varieties, single-face boards feature exposed flutes with a corrugated medium glued to a single linerboard sheet.

2. Single wall.

Single wall. Also called double face, this is the most common variety of board. Single wall boards feature two linerboard sheets with a corrugated medium glued between them.

3. Double wall.

Double wall. A preferred packing material for more delicate goods for its extra protection, double wall boards consist of two layers of corrugated medium between three linerboard sheets.

4. Triple wall

Triple wall. This board has triple corrugated layering for increased durability and resistance to pressure, impact, and bending. Triple wall boards have four linerboard sheets with a total of three corrugated mediums in between each layer.

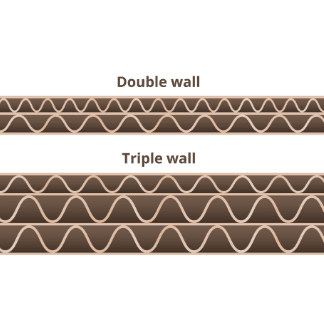

Flute Profiles

There are multiple types of flute profiles available for corrugated board, and their size helps determine their ideal application. For example, while smaller profiles can serve in a structural capacity for retail packaging, larger fluting offers optimal cushioning with superior vertical compression strength. Flutes are categorized based on their structure and wave density, with a letter assigned to each of five categories based on size: A, B, C, E, or F. The flute waves start large with A-flute and decrease in size and density through F-flute. Corrugated boxes typically meet in the middle, using C-flute.

Choosing Your Corrugated Box

WITH THE WIDE VARIETY OF CORRUGATED BOXES AVAILABLE, IT CAN BE CHALLENGING TO DETERMINE THE BEST TYPE FOR YOUR APPLICATION.

It’s important to understand the intended use for the box and its expected handling throughout the shipping and storage process when choosing a corrugated box for your needs. Consider the following information to help guide your decision.

Choosing the Right Strength

Corrugated boxes are known for their durability, and it is board strength that defines the strength level of a particular box. To calculate this strength, you can utilize the edge crush test or the fluting technique. The edge crush test ascertains corrugated box strength by stacking a corrugated board piece and then crushing it, applying force to a standing edge to determine the amount of weight it can handle, or its impact strength. For more information on the different configurations for corrugated boxes and their respective impact strengths based on the edge crush test and other measurements, view this chart from Professional Packaging Systems, Inc. The fluting method combines more than one flute profile in a single box, allowing corrugated box designers to tweak thickness and cushioning and compression strength for the completed fiberboard. For example, manufacturers might use one A-flute layer and two C-flute layers to create a triple-wall board.

Choosing by Type & Application

Closely evaluating the application for a corrugated box is a good starting point when choosing the box type you need because your product’s weight, size, and shape are key factors in that determination. For example, five-panel folders provide the best protection for delicate, flat products like mirrors or glass, while heavy items require a corrugated box with superior strength like a full-overlap box. If your items have more of an unusual shape, telescoping boxes are an ideal solution, while they also work for packaging fragile items. As for board type, single- and double-wall boards are an optimal choice for shipping and industrial packing, respectively, and triple-wall boards are useful for transporting items like hazmat materials that need special handling. Whatever your needs, shopping by corrugated box type is the most efficient way to quickly find the perfect one for your application.

Choosing by Size

Determining the appropriate box size for your goods is essential when selecting boxes for shipping or corrugated boxes for retail use. Alpha Packaging offers corrugated boxes in numerous sizes to accommodate a wide range of dimensional requirements. Shop by box size to find the perfect fit for your items quickly. We offer boxes with inside dimensions as small as 3” x 3” x 3” to as large as 8.5” x 8.5” x 72”.

Choose Alpha Packaging for Your Corrugated Box Needs

As a one-stop-shop corrugated box manufacturer, Alpha Packaging listens to your unique requirements so that we can create the ideal packaging solution for shipping, storing, or displaying your products. Our team draws from over 200 years of combined experience and our extensive catalog of over 13,000 packing materials to create a packaging solution tailored to your specific application.

When working with Alpha Packaging for custom corrugated boxes, we’ll begin with a comprehensive consultation so that our team can fully understand your needs and those of your products. Based on your input, Alpha Packaging will design and manufacture the perfect custom corrugated box that addresses any product challenges. We support you through every step of our manufacturing process with a commitment to superior customer service, on-time order fulfillment, and high-performance boxes.

Contact us with any questions, or request a quote to get started.

CONTACT US TODAY TO LEARN MORE ABOUT OUR CORRUGATED BOX SOLUTIONS, OR REQUEST A QUOTE FOR CORRUGATED BOXES FOR YOUR NEXT PROJECT.